Anode Cells

Why choose UFS Anode Cells?

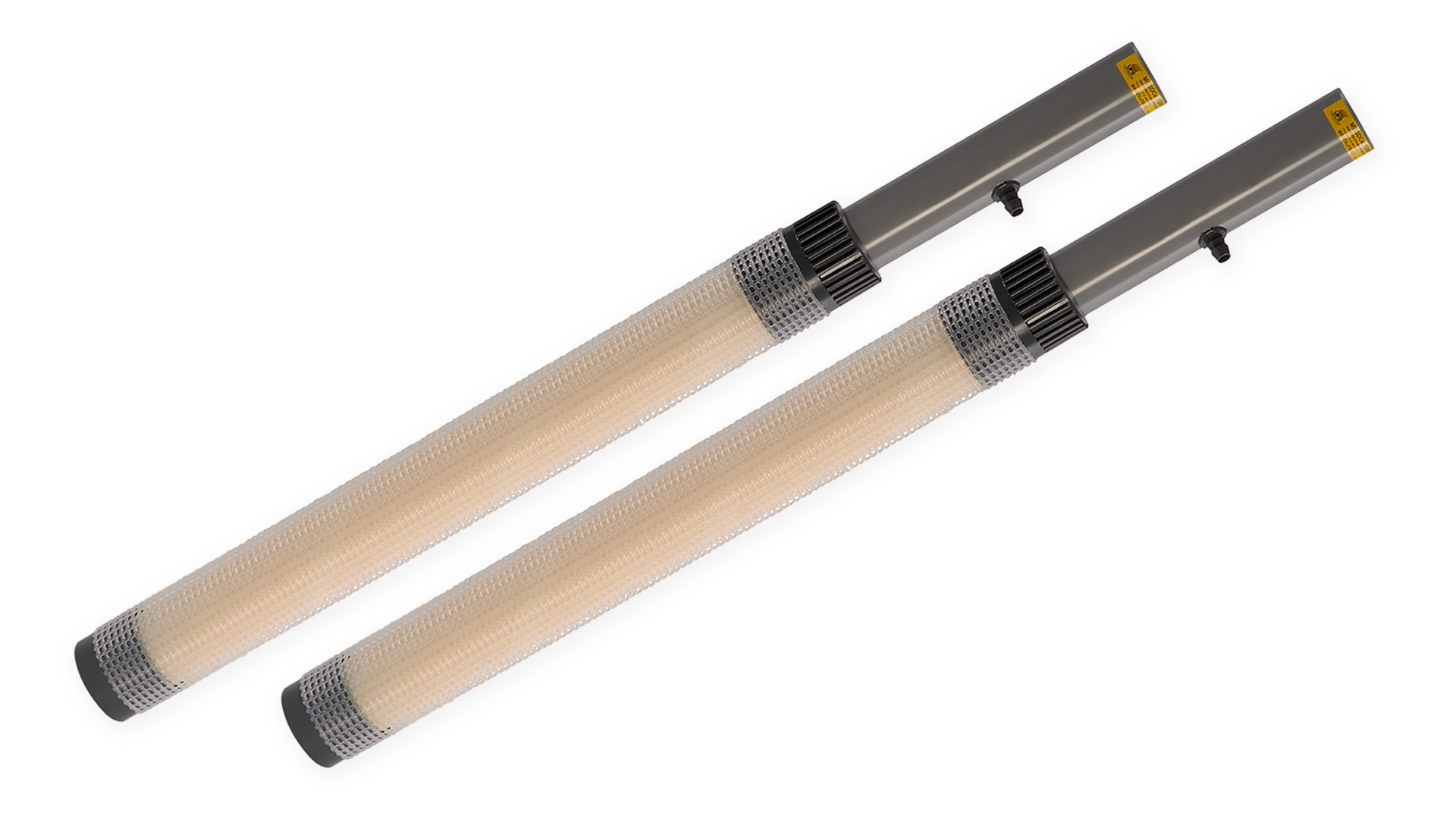

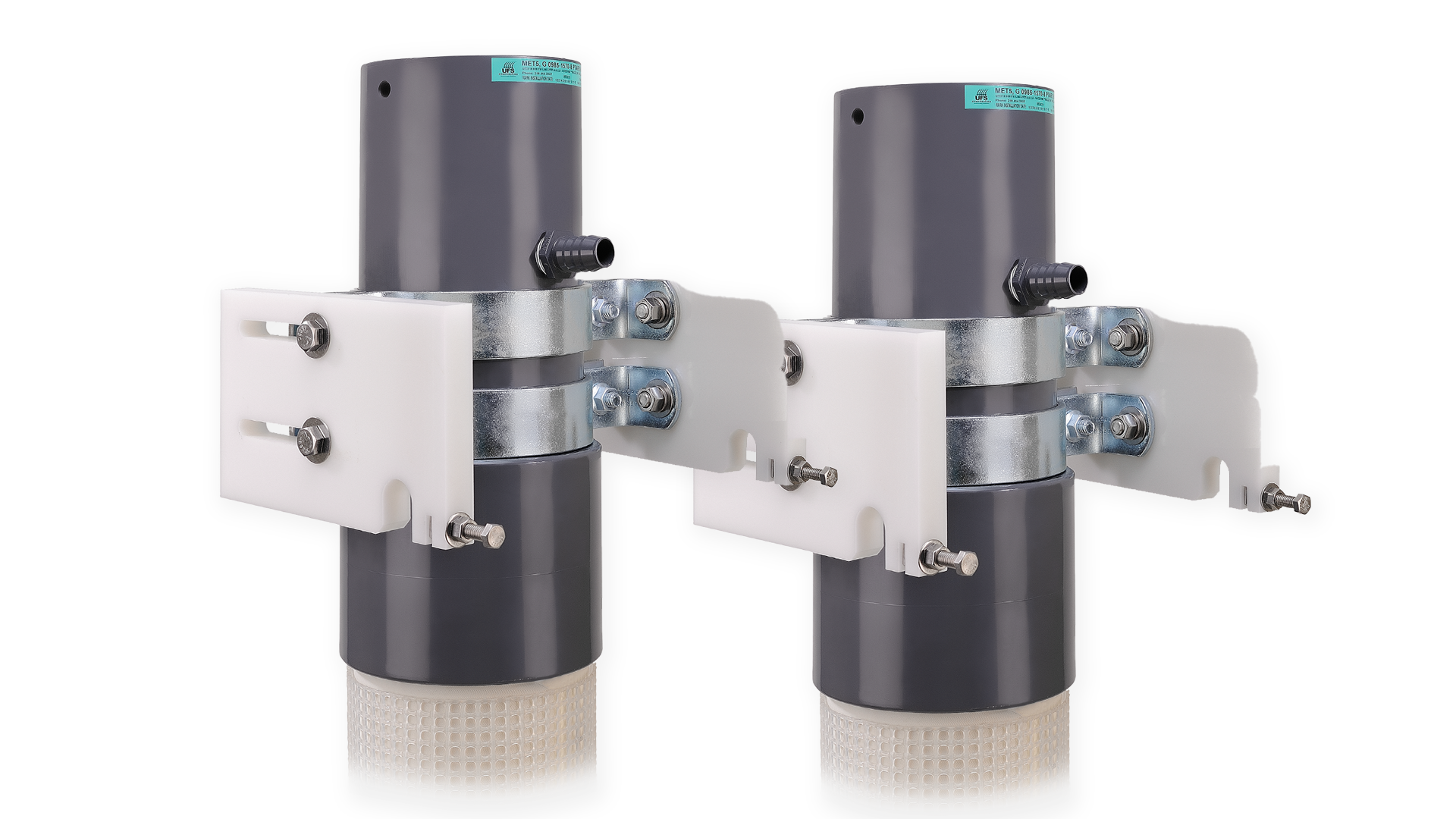

Our two-part construction (with a removable anode inserted inside a membrane shell) is lightweight; easily installed; inspected and maintained; and easily adaptable. With our cylindrical design, the membrane circumference is greater than the anode circumference. This membrane-to-anode ratio means there is more area for electrical current to pass through, lowering current density and giving longer life.

Small Diameter (1.5” and 2”)

Appropriate for parts and general industrial applications

Offers the greatest membrane-to-anode ratio, providing longest possible operational lifetimes

Suitable for indexing or hoist type E-coat paint systems

Available in most diverse selection of anode materials

Large Diameter (3” and 5”)

Appropriate for automotive paint systems

Has all the advantages of tubular cells with fewer required connections (compared to smaller diameter anode cells)

Easily retrofits into existing E-coat systems, replacing box and c-cells.

Closed Top / Low Profile / Pressurized

Appropriate for hoist or indexing paint systems to keep paint from entering inside anode cell

Can be fully submerged

Several bulkhead designs are offered to reduce necessary working height of the Anode Cell to a minimum

Roof & Floor

Provides additional throw-power to coat complex or difficult-to-reach areas

Can be installed on the top and bottom of the tank, respectively, to supplement side cells

Available with a membrane shell (flushable) or as a Bare Electrode

Several configurations are offered, engineered for specific E-coat system needs

Purchasing Process

To begin the purchase process, please complete the contact form shown. Our Sales Team will be in touch within 24 business hours to ensure you make the right selection based on your specific needs.

In the event your need is urgent please feel free to reach out via phone during normal business hours.

Contact Info

Phone - (219) 464-2027

Email - info@ufsc.com

Office Hours (CST)

Monday - Thursday 7am - 4:30

Friday 7am - 2pm

Saturday & Sunday Closed